What is a “Breadboard”?

Literally, a breadboard is a plank of wood intended for cutting bread on. Think early 1900s here, before sliced bread, and before transistors. Even basic projects were large by today's standards. People would take a bread board and use it as a platform to support the tubes, transformers, capacitors and other large components. Bread boards came to be associated with electronics experimenters because they were inexpensive, sturdy and readily available, and it's easy to move components around on them.

|

Old-style breadboard (Source)

Nowadays, the term “breadboard” can apply to lots of different things.

One type of experimenter's board is solderless breadboard, also called plugboard. You just plug components into the holes and they're connected by copper strips underneath.

|

Solderless breadboard, a.k.a. plugboard (Source)

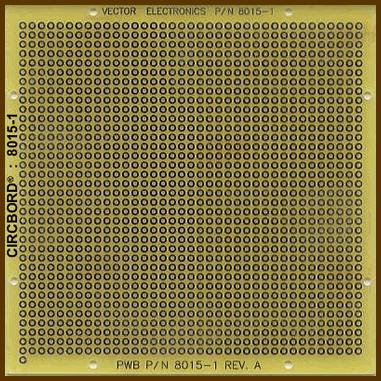

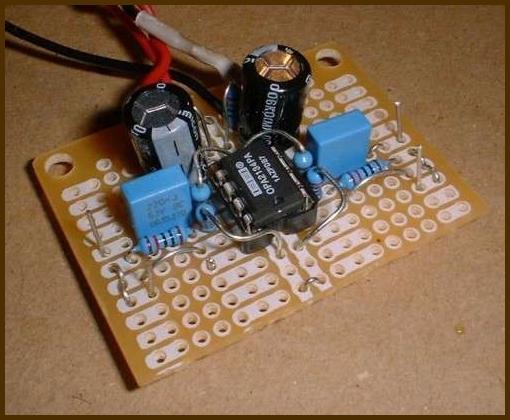

The other major type of modern experimenter's board is perfboard. At its most basic, perfboard is some type of circuit board material with holes punched in it at regular intervals, usually 0.1".

If you see the term “perfboard” alone, it often refers to just plain perforated circuit boards. You stick the leads of components through the holes and solder the leads to the leads of other components. It's primitive, but it works.

More often, perfboard has a copper pattern printed on its surface, to which you can solder components. The simplest type is pad-per-hole, which simply has a ring of copper around each hole. The advantage of this over plain perfboard is that each component is soldered to the board rather than to each other, so it's easier to work with and the project is more stable.

|

Pad per hole perfboard (Source)

You can also find perfboard types with various copper patterns that connect multiple holes. In the image below, the white markings on the top of the board tell you where copper is on the bottom side. This particular type has a complicated pattern: there are two bus strips down the center of the board, 2-hole pads on the edges of the board, and 3-hole pads and pad-per-holes between the two.

|

Complicated perfboard

Other terms you may encounter are:

Vectorbord, Veroboard — These are the most common brands of perfboard. Branded perfboard is usually the higher-quality stuff, made more for experimentation than assembling known-working circuits. Cheap perfboard is usually unbranded or it's some kind of “house” brand.

stripboard — This is perfboard with rows of copper strips on it. You cut the strips to form shorter rows of connected holes. This offers a balance between the ultimate flexibility of pad-per-hole board with the convenience of a patterned perfboard.

protoboard — This term is nearly as vague as “breadboard.” Most often it refers to copper-patterned perfboard.

Which is the best type? Well, it depends on your needs. Solderless breadboard is convenient, but it's expensive and it's only good for temporary experiments. Also, the concept is flawed by inherent parasitic capacitances and inductances; Bob Pease calls them “white slabs of trouble” because they decrease the chances of success so much, particularly with analog circuits. Plain perfboard is cheap and simple for small projects, but due to the lack of copper patterns the wiring on them often becomes a rats nest of interconnected wires. Pad-per-hole perfboard is a little more mechanically sound, but not much better in terms of neatness. Patterned perfboard can give the neatest layouts if you can find the right pattern and you plan your layout carefully around it, but it's the most expensive type.

Beware also that there are varying grades of perfboard. The cheapest type has unclad copper pads and the pads are easy to rip off the board if you stress them. This type is okay for soldering down a known-working circuit, but not very good for experimenting. More expensive perfboard types have stronger pads, the pads are often clad with tin so they accept solder more readily, and the board itself is more rugged. You can spend anywhere from a few dollars for a board of several square inches up to about twenty bucks for the same size board, depending on quality. The expensive stuff is only useful if you expect to be modifying the circuit or you need the greatest possible durability.